(727) 808-8602

| Home | Latest New Products | Customers' Rides | Orders, Terms and Conditions |

| What a crank-scraper is and other technical info... | Some comments on our products... |

|

(727) 808-8602

|

crankscraper, crank-scraper, crank-scrapper, oil wiper, crank, crankshaft, rod-bearing, main-bearing, connecting-rod, counterweight, piston, windage, windage-tray, windage-cloud, oil pan, oil-pan, oil-aeration, oil-foaming, oil-cloud, racing, drag racing, road racing, drag-race, road-race, road-course, drift, drifting, time-trial, performance, power, horsepower, HP, torque, TQ, friction, vacuum, economy, engine, motor

Copyright 2002-2025 © All rights are reserved on our product designs.

Supplemental Instructions for Installing Teflon® Scrapers

Note: Initially, the Teflon® insert is not within the substructure: the (2) two washers in between the scraper substructure and clamping plate serve to mimic the thickness of the Teflon® while trial fitting. Please discard the washers once you are ready to place the Teflon® between the substructure and clamp.

Trial fit the substructure and clamping plate alone on the engine and slowly but fully rotate the bottom end. If there is interference at any point -- do not force past. You will need to relieve the substructure and clamp in that area – leave a minimum of 1mm or .040” clearance.

Place the Teflon® sheet or 'insert' between the substructure and clamp.

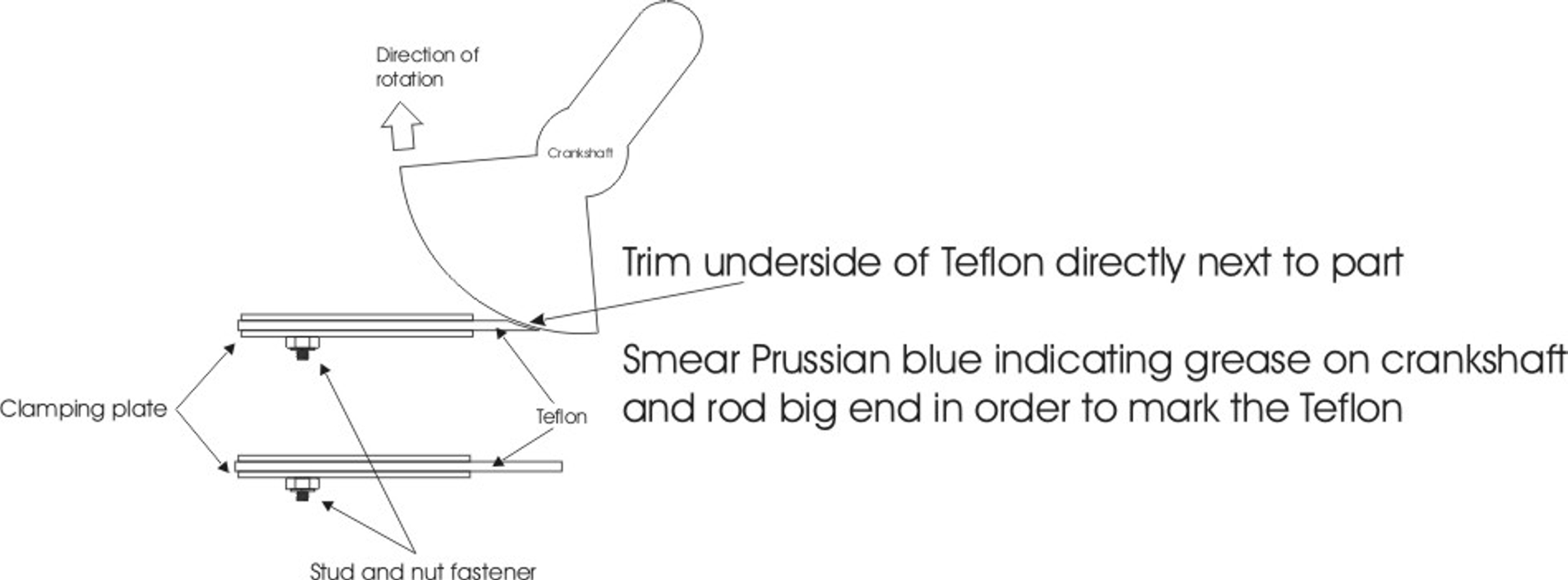

Gently rotate the bottom end and note where it hits the Teflon® sheet. Trim the Teflon® until “light” contact is made. “Light” contact means that there is some drag when the part slides against the Teflon®. It is acceptable if the Teflon® deflects (moves) slightly when this happens.

Note: If the counterweight has large drillings for balancing that catch on the edge of the Teflon® then you should trim the Teflon® in that area back until there is no contact. A casting or forging seam or other protuberance might be the only point of contact. You can choose to smooth these away on the parts BUT you need to do this BEFORE the assembly is balanced. Otherwise simply adjust the Teflon®.

It may be helpful to smear the crankshaft counterweights and throws as well as the rod big ends with the included tube of Prussian blue indicating grease. This will leave marks on the Teflon® where it is touching.

The Teflon® can be easily trimmed using a single-edged razor, an X-Acto knife, a small file or Dremel-type rotary tool. If you use a rotary tool choose bits with plastic cutting flutes (they are wider than for grinding on metal). Teflon® or PTFE has the consistency of a hard synthetic wax.

When you are done trimming the Teflon®, replace and tighten all the retaining nuts (use a ¼”socket or small wrench) to 35 inch-lb torque. Some customers like to use a drop of a medium strength thread locking compound. The nuts are milspec locknuts. Once again rotate the bottom end and ensure that only slight drag is present against the Teflon®.

Reinstall any parts for your engine that you removed to install the scraper.

Refill the engine with oil and a fresh filter. Start engine and allow it to come to operating temperature. It is normal for a thrumming sound to be present as the bottom end beds into the Teflon®. Work the clutch in and out if you have a manual transmission and rev the engine gently. After approximately 50 miles of normal stop and go driving or twenty to thirty minutes of static operation the scraper should be fully bedded in and achieved a running clearance of about .001”. The thrumming sound, if originally present, should be minimal.

Change the oil and filter. If you doing a fresh rebuild on the engine then the normal break-in period and oil will simultaneously work for the scraper fitment as well.

|

Copyright 2002-2025 © All rights are reserved on our product designs -- a great deal of hard work goes into each one. Teflon® is a registered trade mark of E.I. du Pont de Nemours and Company. Only DuPont makes Teflon® resin sourced by Ishihara-Johnson Crank Scrapers from authorized DuPont licensees. We Ship

|