|

|

|

We can do custom stroker or knife-edge crank designs. We can provide templates for initial fitting and adjustment. Templates cost $100 and are a separate charge from the scraper pattern chosen.

We have included some representative pictures of the scrapers we make. If you would like to see a picture of a particular scraper please ask -- we would be more than happy to send one through.

When available (please enquire) our zero-clearance Teflon® scrapers run an additional $130.00 to the cost of the standard steel scraper unless noted.

Remember, your vehicle may have an engine made by a different manufacturer so check both product lines. If you are still unsure, please contact us.

crankscraper, crank-scraper, crank-scrapper, crank, crankshaft, rod-bearing, main-bearing, connecting-rod, counterweight, piston, windage, windage-tray, windage-cloud, oil pan, oil-pan, oil-aeration, oil-foaming, oil-cloud, racing, drag racing, road racing, drag-race, road-race, road-course, drift, drifting, time-trial, performance, power, horsepower, HP, torque, TQ, friction, vacuum, economy, engine, motor

| Toyota

|

Copyright 2002-2026 © All rights are reserved on our product designs.

A series engines: 1A-C, 1A-U; 2A, 2A-L, 2A-LC, 2A-U, 2A-LU; 3A, 3A-L, 3A-LC, 3A-U, 3A-LU, 3A-HU, 3A-SU, 4A, 4A-C, 4A-ELU, 4A-F, 4A-FE, 4A-FHE, 4A-GE (1st, 2nd, 3rd, 4th, 5th gen; Blue top, Red top, Black top, Silver top) (16V and 20V); 4A-GZE, , 4A-L, 4A-LC; 5A-F, 5A-FE, 5A-FHE, 6A-FC; 7A, 7A-FE, 8A, 8a-FE scrapers are available in steel ($109.95) and Teflon® bladed ($239.95) versions.

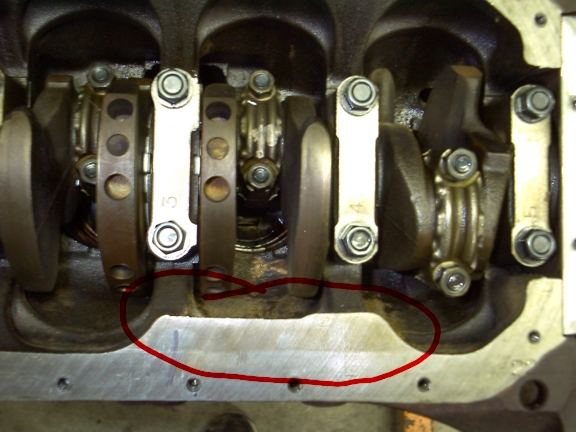

Important note: It has been brought to our attention that there are some engines like very late 4AGZE blocks and 4AFE that have a casting variation that intrudes into the 3rd and 4th bay area but otherwise use a 16V type pan and tray. We can make scrapers to fit this variation with no problem and at no additional cost but you need to specifically request it at the time the order is placed. If you have a bare block this area can be easily ground away.

The scrapers include a center baffle to help segregate bays 1-2 and 3-4 from each other. This baffle installs under the center main bearing cap bolts.

This picture shows the new dual scraper and baffle next to the modified windage tray:

There is a similar scraper for use with the 7A -- it is thinner on the oil pan perimeter because of the upper alloy sump used on the 7A.

Modified 4A Windage Tray

A modified windage tray for a Toyota 4A series engine such as the 4AFE, 4AGE, 4AGZE and so on. If you have the 20 valve which has a different oil pan flange pattern please let us know as we can modify the tray to fit. The pictures below include parts from the scraper kit:

It is a dual tray which means it has two separate layers. (Toyota part number 12122-16011 Plate, oil pan baffle) customer must send a new or good usable core. We have been made aware that this part is NLA from Toyota so use great care in removing it from your engine. Generally, if a flange has been bent during removal it can be straightened. The inner layer is made from suspended directional screening which has been used for many years in windage trays to capture and dissipate the energy of high speed oil droplets which can cause foaming or bounce back up and be hit again and again. The solid tray underneath has been slotted and drilled to allow scavenged oil to freely drain through. The added slots and holes are not so large, however, so as to allow splashing sump oil to contact the rotating assembly. The dual windage tray is the most advanced system available for this engine and would complement and improve even a dry sump system. The dual windage tray runs $189.95; the modified tray for the 20v runs $239.95.

Pics of 20v tray:

Most recent version of 20v tray:

with 20v steel scraper:

20V Teflon® scraper:

Knife-edged Teflon® bladed scraper (for a custom crank) that works in harmony with the tray:

Scraper sitting in 20v pan: Scraper sitting in 20v pan:  The 4A series windage tray is complemented by the Dual 4A series crank scrapers we also manufacture. The 4A series windage tray is complemented by the Dual 4A series crank scrapers we also manufacture.

|

|